UGMS / ATGMS

Unattended Geometry Measurement Systems, aka Autonomous Track Geometry Measurement Systems

Conventional track measurement technologies require the following:

- Dedicated track geometry vehicles

- Rail-bound for loaded measurement

- Hi-rail vehicles for unloaded measurement

- Trained operators

- Track time that can interrupt revenue service

- Generally testing at track speed with rail-bound

- Hi-rails are limited to 30mph – 40 mph

The capital investment for a track inspection car, creating a team of trained operators, and scheduling track time for inspection are the drawbacks of conventional track measurement culture.

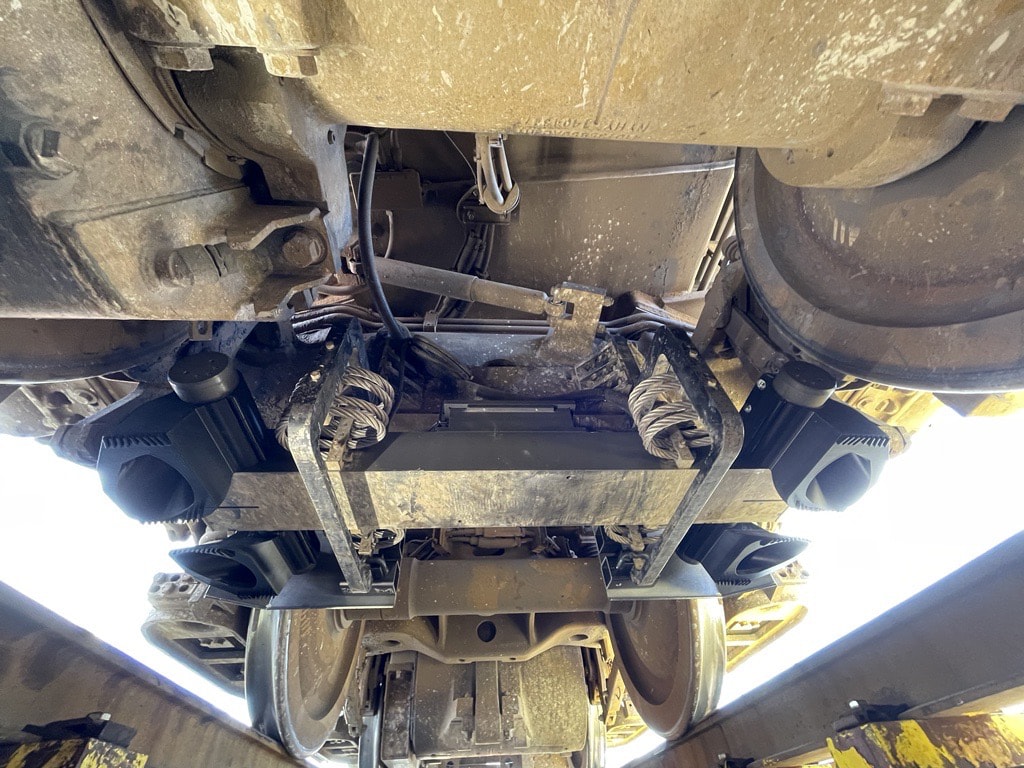

Holland offers an Autonomous Track Geometry Measurement System, ATGMS, the lowest-cost track measurement technology without compromising quality. Due to Argus’ compact, lightweight, and low-power features, Holland can enhance revenue-service freight and passenger locomotives with track geometry and rail profile measurement capability. In addition, our Portable Inspection systems which are used by hi-rail vehicles, can be operated autonomously. UGMS/ATGMS allows track measurement at track speed, under an operational load environment, and without any track time demand under revenue service locomotives and railcars.

UGMS provides the following foot-by-foot loaded or heavy track geometry:

- Track gauge and change rate (tight gauge, nominal gauge, wide gauge)

- Cross level/superelevation

- Surface and alignment (varying chord lengths up to 124 ft)

- Warp and twist (varying chord lengths)

- Runoff

- Degree of curvature

- Vmax and unbalance

- Additional custom geometry channels

UGMS systems deliver the following data to customer’s on-premise or cloud servers with the format and frequency they provide:

- Foot-by-foot located track geometry measurements

- Up to three different level of track geometry exceptions/defects, such as red, orange and yellow on designated measurements,

- Near-real time track geometry exception notifications to the designated personnel via email or text,

- Processed rail profile measurements by Rangecam algorithms to provide;

- Rail cant angle

- Rail weight / size

- Vertical and gauge face wear

- Total wear or loss area

- Rail head slope

- Gauge face angle

- Base-to-height ratio

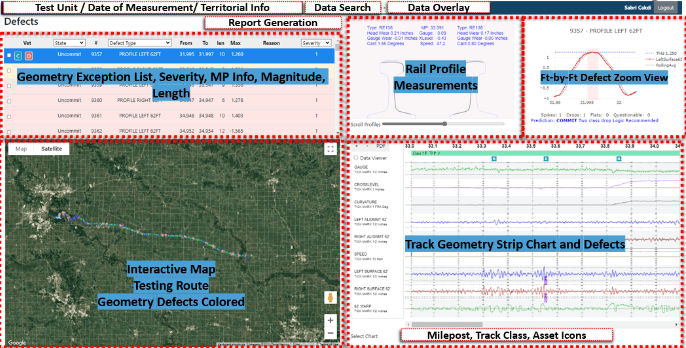

In addition to automated data and report delivery, Holland created the web platform – Genesis – to visualize, analyze and report Argus UGMS measurements. Genesis web platform includes the following sections and functionalities;

-

- The UGMS unit ID, date of measurement and territorial information selection (called “Run”),

- Historical data search based on territorial information and date,

- Automated data overlay to visualize geometry changes. Platform also allows manual fine tuning of the data alignment,

- Interactive maps that shows the measurement route (green line), defect zones defined with severity (red, orange, yellow), indicators for curve, grade crossings, switch points, mileposts and more,

- Defect list with defect type, total length, milepost range and severity,

- Foot-by-foot zoom view section shows the measurement of every foot, where defect exceeded and dropped below the threshold,

- Geometry strip chart with defect labels, milepost, track class and icons for grade crossings, switch and frogs, diamond crossings, bridge and any other asset with GPS information available,

- Rail view section with rail measurement overlaid with rail size and rail wear values,

- All sections on Genesis web page are synchronized with each other. For instance, clicking a defect from the list takes the user to the location of defect on the map, associated rail profile measurement, defect zoom view and location in the strip chart,

- Report section to submit a daily pdf track geometry report including strip charts, defect lists and curvature summaries