Rangecam Reporting Software

Rangecam is Holland's advanced track inspection data analysis and management software. Rangecam offers unparalleled manual and automated functionalities for data cleansing, preprocessing, data exploration, trend analyses, visualization and reporting for data-driven maintenance planning.

Centralized Track Data Management

Rangecam combines railroad's history of track geometry, rail profile, gauge restraint measurement (GRMS), rail flaw and other data in a single database for system-wide analyses and reports.

Track Inspection Data Analysis

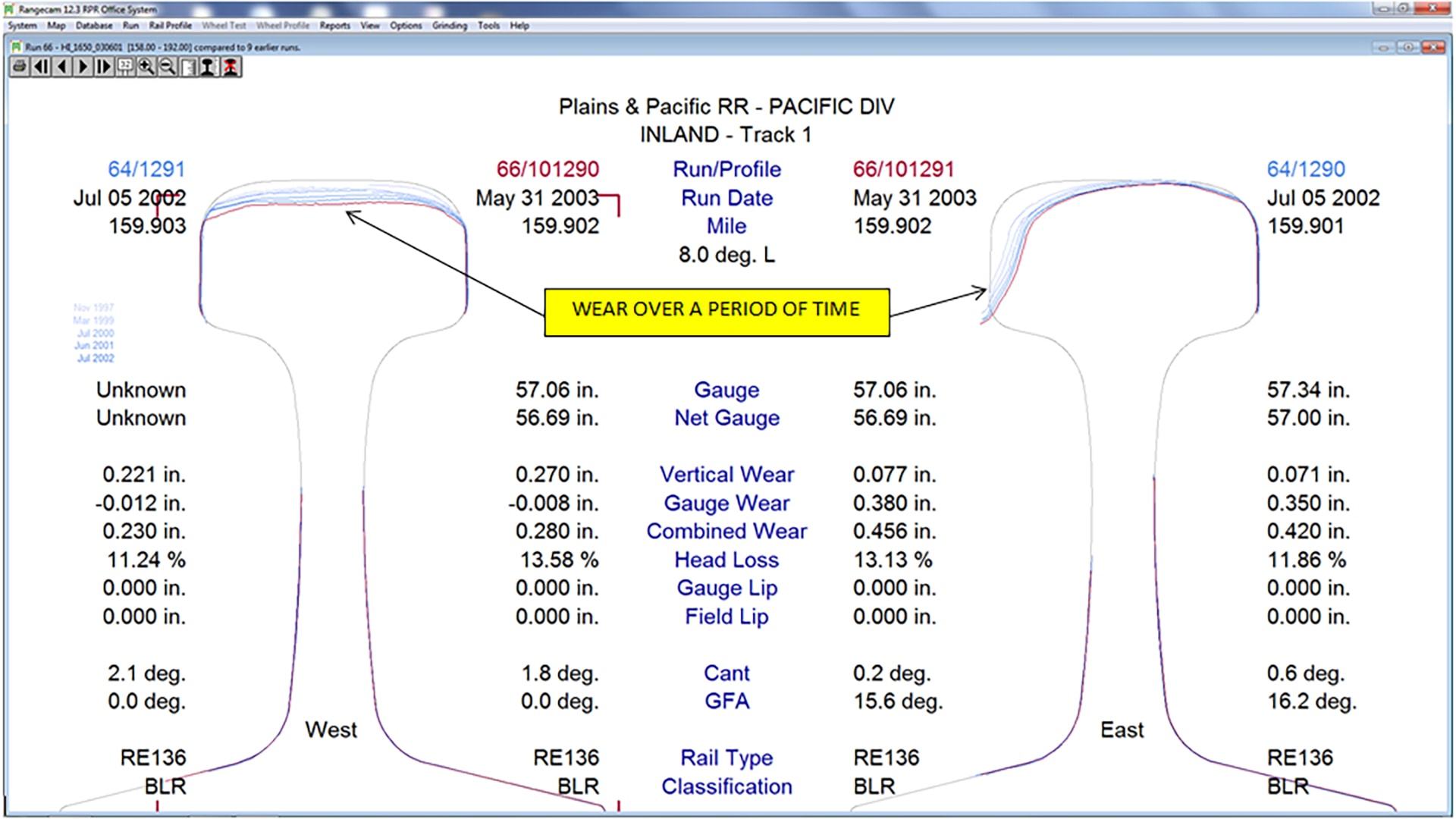

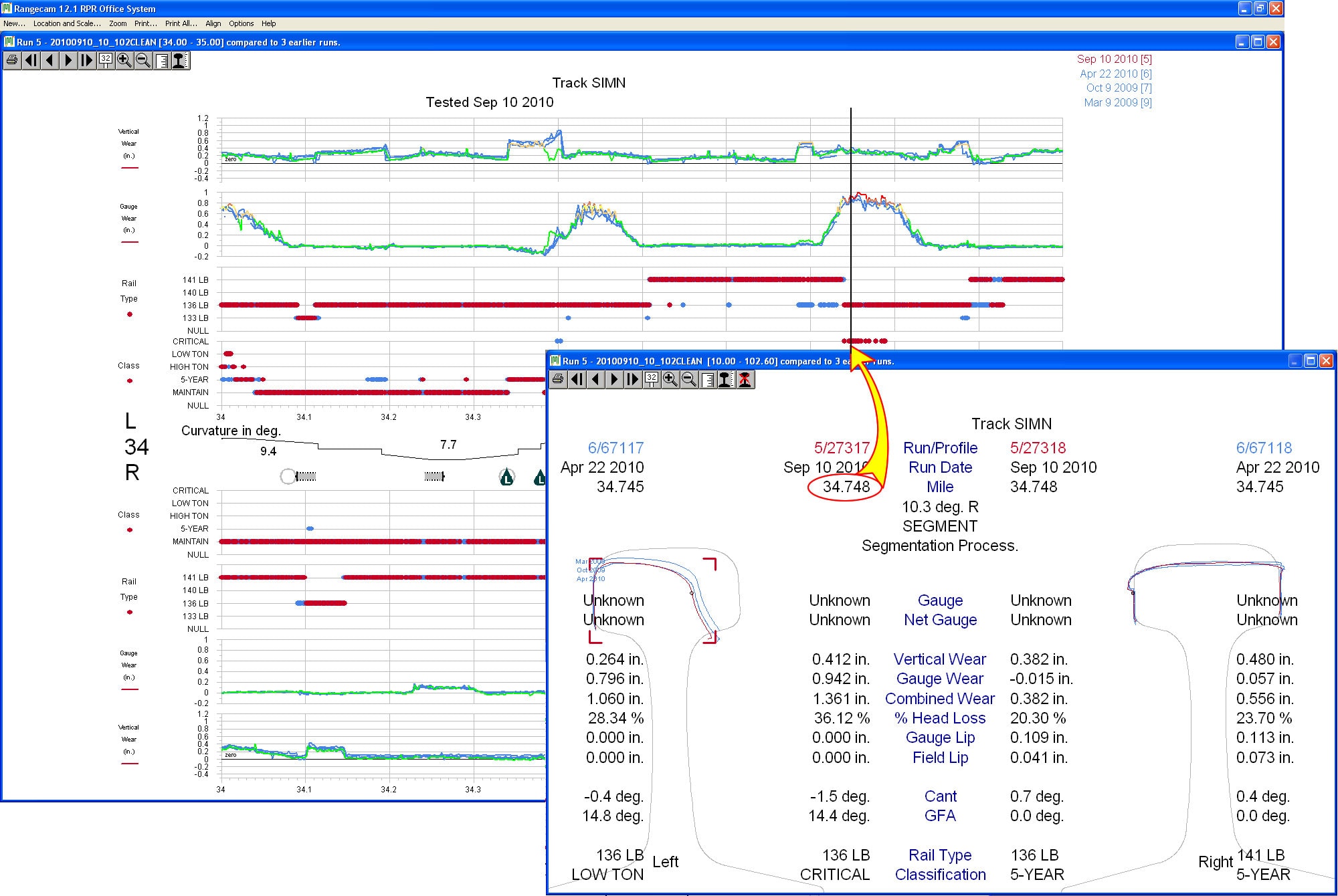

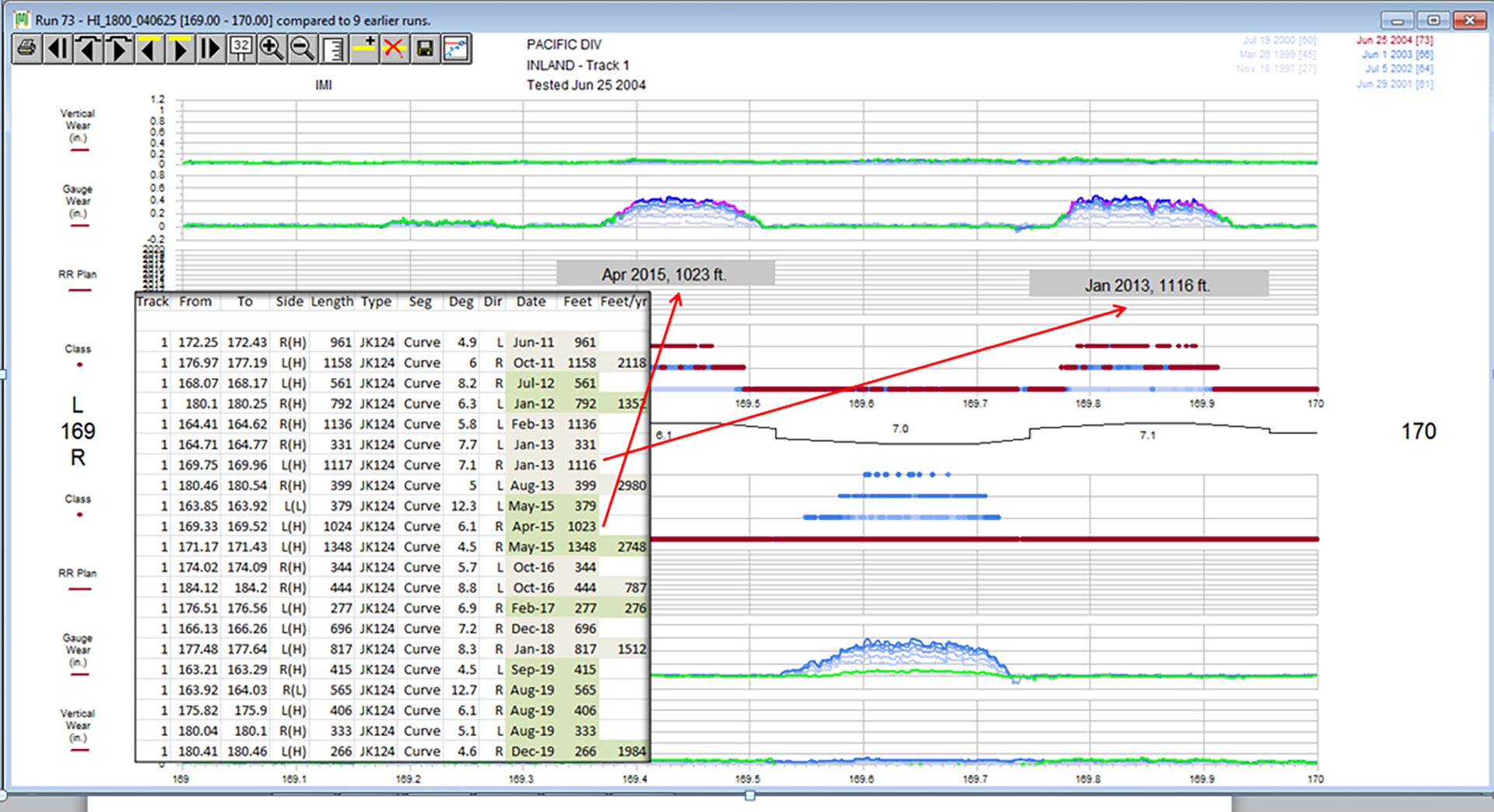

- Intuitive graphs of aligned and overlaid historical track inspection data to reveal track changes overtime

- Automated or manual rail weight / size identification and rail inventory report for the network

- Quick, fast and flexible data query tools. Engineers and maintenance planners can search any track conditions to prioritize for maintenance, such as; “ Bring the locations where 136-lb rail has more than ¾-inch vertical, ½-inch gauge wear and combination of reverse rail cant and gauge is more than 1-inch wide”

- Rail wear rate and replacement prediction based on tonnage and historical data

- Tie performance summary and replacement reports based on track geometry and GRMS data

- Curve performance analysis to reveal the effectiveness of superelevation changes, friction modifiers, grinding and changing operation conditions

Wheel and Rail Interaction Analysis

- Analyze wear condition of wheels such as flange angle, flange height, flange thickness, taper angle, and more

- Visualize and quantify the wheel and rail interaction by identifying contact locations under varying lateral wheelset position

- Reveal conformal and non-conformal wheel and rail contact conditions given measured profiles and track geometry

- Provide critical information to wheel truing and rail grinding for optimum wheel and rail life

Rangecam Rail Grinding Analyst

- Provide data-driven grinding planning by using existing grind templates or designing custom ones.

- Visualize and quantify necessary metal removal for grinders

- Overlay pre and post-grinding measurements with the template, generate grind quality report

- Different templates can be automatically assigned to curves of different degrees

- Templates are automatically overlaid

- Grinding patterns and speeds can be entered for any number of passes

Looking for more information? Check out the Holland Library for additional literature and videos, or contact us.