UGMS (Unattended Geometry Measurement Systems)

Conventional track measurement technologies require the following:

- Dedicated track geometry vehicles

- Rail-bound for loaded measurement

- Hi-rail vehicles for unloaded measurement

- Trained operators

- Track time that can interrupt revenue service

- Generally testing at track speed with rail-bound

- Hi-rails are limited to 30mph – 40 mph

The capital investment for a track inspection car, creating a team of trained operators, and scheduling track time for inspection are the drawbacks of conventional track measurement culture.

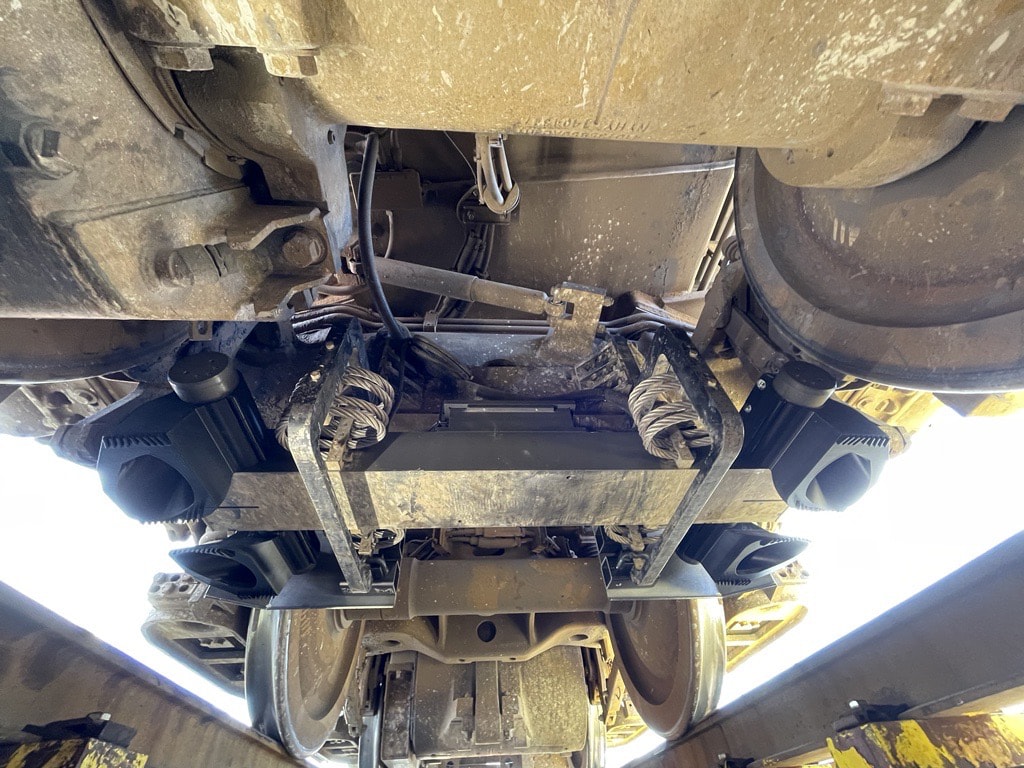

Holland offers an autonomous track geometry and rail profile solution, UGMS, the lowest-cost track measurement technology without compromising quality. Due to Argus’ compact, lightweight, and low-power features, Holland can enhance revenue-service freight and passenger locomotives with track geometry and rail profile measurement capability. In addition, our Portable Inspection systems which are used by hi-rail vehicles, can be operated autonomously. UGMS allows track measurement at track speed, under an operational load environment, and without any track time demand under revenue service locomotives and railcars.

UGMS provides the following foot-by-foot loaded or heavy track geometry:

- Track gauge and change rate (tight gauge, nominal gauge, wide gauge)

- Cross level/superelevation

- Surface and alignment (varying chord lengths up to 124 ft)

- Warp and twist (varying chord lengths)

- Runoff

- Degree of curvature

- Vmax and unbalance

- Additional custom geometry channels

UGMS systems deliver the following data to customer’s on-premise or cloud servers with the format and frequency they provide:

- Foot-by-foot located track geometry measurements

- Up to three different level of track geometry exceptions/defects, such as red, orange and yellow on designated measurements,

- Near-real time track geometry exception notifications to the designated personnel via email or text,

- Processed rail profile measurements by Rangecam algorithms to provide;

- Rail cant angle

- Rail weight / size

- Vertical and gauge face wear

- Total wear or loss area

- Rail head slope

- Gauge face angle

- Base-to-height ratio

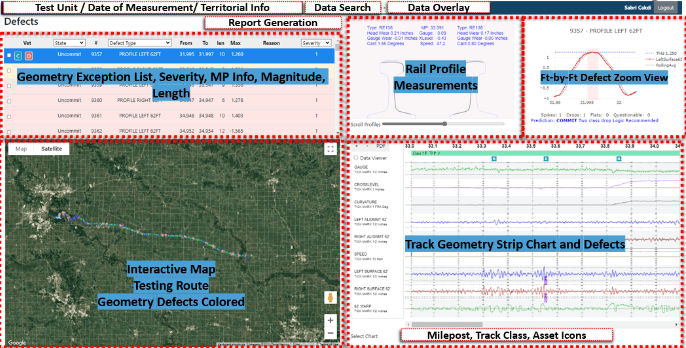

In addition to automated data and report delivery, Holland created the web platform – Genesis – to visualize, analyze and report Argus UGMS measurements. Genesis web platform includes the following sections and functionalities;

-

- The UGMS unit ID, date of measurement and territorial information selection (called “Run”),

- Historical data search based on territorial information and date,

- Automated data overlay to visualize geometry changes. Platform also allows manual fine tuning of the data alignment,

- Interactive maps that shows the measurement route (green line), defect zones defined with severity (red, orange, yellow), indicators for curve, grade crossings, switch points, mileposts and more,

- Defect list with defect type, total length, milepost range and severity,

- Foot-by-foot zoom view section shows the measurement of every foot, where defect exceeded and dropped below the threshold,

- Geometry strip chart with defect labels, milepost, track class and icons for grade crossings, switch and frogs, diamond crossings, bridge and any other asset with GPS information available,

- Rail view section with rail measurement overlaid with rail size and rail wear values,

- All sections on Genesis web page are synchronized with each other. For instance, clicking a defect from the list takes the user to the location of defect on the map, associated rail profile measurement, defect zoom view and location in the strip chart,

- Report section to submit a daily pdf track geometry report including strip charts, defect lists and curvature summaries